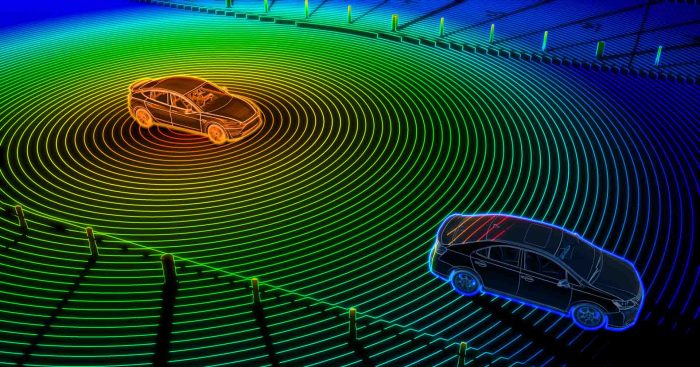

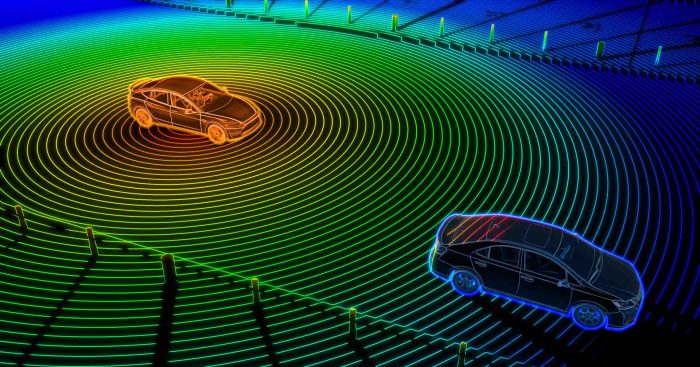

LiDAR technology in smartphones: cost implications for manufacturers. The integration of LiDAR into smartphones promises a revolution in mobile sensing capabilities, enabling advanced augmented reality applications, improved depth perception for photography, and enhanced autonomous navigation features. However, this technological leap comes at a cost. This analysis delves into the multifaceted financial considerations facing manufacturers, examining component costs, manufacturing processes, integration challenges, and market dynamics to understand the price implications of incorporating this groundbreaking technology.

From the initial research and development expenditure to the complexities of integrating miniaturized LiDAR systems into existing smartphone designs, the financial burden is substantial. This report dissects the various cost drivers, comparing LiDAR’s financial impact with that of other smartphone components, and explores potential avenues for cost reduction through economies of scale and technological advancements. Ultimately, understanding these cost implications is crucial for manufacturers to strategize pricing and market penetration of LiDAR-enabled smartphones.

Component Costs

Integrating LiDAR into smartphones presents significant cost challenges for manufacturers. The price point of a consumer device is heavily influenced by the bill of materials, and LiDAR, being a relatively complex technology, adds substantially to this cost. Understanding the individual component costs and potential for cost reduction is crucial for widespread adoption.

The cost of a smartphone LiDAR system is determined by the price of its individual components, the quantity needed per device, and the manufacturing processes involved. While precise pricing fluctuates based on supply and demand, a general overview can provide insight into the cost structure.

LiDAR Component Cost Breakdown

The following table provides an estimated breakdown of the costs associated with the core components of a smartphone LiDAR system. Note that these figures are approximate and can vary significantly based on the specific technology used, supplier, and volume purchased. These costs are also per unit.

| Component | Cost per Unit (USD) | Quantity per Phone | Total Cost (USD) |

|---|---|---|---|

| Laser Emitter | 5-10 | 1 | 5-10 |

| Photodetector Array (Receiver) | 8-15 | 1 | 8-15 |

| Processing Unit (ASIC/DSP) | 15-25 | 1 | 15-25 |

| Optical Lenses and Filters | 3-7 | 1 | 3-7 |

| Packaging and Assembly | 2-5 | 1 | 2-5 |

| Subtotal | 38-62 |

It is important to note that this is a simplified representation. Additional components like power management ICs, signal conditioning circuits, and supporting software contribute to the overall cost.

Comparison of LiDAR Technologies

Different LiDAR technologies offer varying performance and cost profiles. The choice of technology significantly impacts the overall price of the smartphone.

- Flash LiDAR: Generally less expensive to manufacture than Time-of-Flight (ToF) LiDAR due to its simpler design. However, it may offer slightly lower accuracy and range.

- Time-of-Flight (ToF) LiDAR: Typically more expensive due to the complexity of the timing mechanisms and higher precision requirements. Offers better accuracy and range compared to Flash LiDAR.

Economies of Scale in LiDAR Manufacturing

A significant factor influencing the cost of LiDAR in smartphones is the potential for economies of scale. As the demand for LiDAR-equipped smartphones increases, manufacturers can leverage higher production volumes to negotiate lower component prices and optimize manufacturing processes. This can lead to a substantial reduction in the overall cost per unit. For example, Apple’s mass production of iPhones has historically allowed them to significantly reduce the cost of individual components over time. Similar cost reductions are expected as LiDAR adoption grows in the smartphone market.

Obtain access to water resistant and shockproof phone cases for outdoor adventures to private resources that are additional.

Manufacturing Processes

Integrating LiDAR into smartphones presents significant manufacturing challenges, demanding precise alignment, miniaturization, and robust quality control. The process differs considerably from the assembly of more established components like cameras, necessitating specialized equipment and expertise. This section details the manufacturing steps involved and contrasts them with traditional smartphone component manufacturing.

The manufacturing of LiDAR for smartphones is a complex multi-step process requiring high precision and cleanroom environments. The integration demands a high level of precision and sophisticated assembly techniques, pushing the boundaries of current manufacturing capabilities.

LiDAR Component Fabrication

The creation of the LiDAR module itself begins with the fabrication of its core components. This involves sophisticated micro-machining techniques to create the tiny mirrors, lenses, and other optical elements. The process often utilizes techniques like deep reactive-ion etching (DRIE) to achieve the necessary precision and miniaturization. Subsequently, these components are assembled and tested individually before integration into the larger module. The yield rate at this stage is crucial, as defects in individual components can lead to significant losses.

Module Assembly and Packaging

Once the individual components are fabricated and tested, they are assembled into the complete LiDAR module. This is a highly precise operation, requiring robotic systems and specialized tooling to ensure accurate alignment and bonding. The process often involves several stages of alignment and testing to ensure the functionality of the assembled module. The completed module is then packaged to protect it from environmental factors and to allow for seamless integration into the smartphone. This packaging process requires careful consideration of thermal management and protection against shock and vibration.

Smartphone Integration

Finally, the completed LiDAR module is integrated into the smartphone chassis. This involves precise placement and connection to the phone’s main board. The process is carefully orchestrated to ensure optimal signal transmission and minimal interference with other components. The placement must also consider factors like thermal dissipation and structural integrity. This stage often involves automated assembly lines and rigorous quality control checks to ensure that the LiDAR module functions correctly within the phone’s overall system.

Challenges and Complexities

Manufacturing LiDAR for smartphones presents unique challenges compared to other components. The extremely tight tolerances required for optical alignment and the miniaturization of the components demand high-precision manufacturing processes and sophisticated equipment. Yield rates can be significantly lower than those for other smartphone components due to the complexity of the process and the sensitivity of the optical elements. Furthermore, the cost of the specialized equipment and the skilled labor required adds to the overall manufacturing expense.

Comparison with Camera Manufacturing

While both LiDAR and camera modules involve optical components, their manufacturing processes differ significantly. Camera module assembly, while precise, typically involves larger components and less demanding alignment tolerances. The manufacturing processes for cameras are more mature and established, leading to higher yields and lower costs. LiDAR manufacturing, on the other hand, requires more specialized equipment, cleanroom environments, and highly skilled technicians, contributing to a higher cost of production. The miniaturization challenges faced in LiDAR manufacturing are far more stringent than those encountered in the production of camera modules. The complexity of the optical system in LiDAR also contributes to a higher failure rate during assembly and testing.

Integration Challenges

Integrating LiDAR into smartphones presents significant technical hurdles that directly impact manufacturing costs. Miniaturizing the complex sensor array while maintaining performance and managing power consumption and heat generation are key challenges. These issues necessitate innovative design and manufacturing processes, driving up the overall price of the device.

The primary challenge lies in the inherent physical limitations of LiDAR technology. Current LiDAR systems, even those designed for compact applications, require a certain volume to house the necessary components: the laser emitter, receiver array, and associated electronics. Shrinking these components to fit within the slim profile of a modern smartphone necessitates advanced micro-fabrication techniques and potentially compromises performance. Furthermore, the power consumption of LiDAR is considerably higher than other smartphone sensors, requiring larger batteries or more efficient power management systems, both of which add to the cost. The increased power consumption also generates heat, which needs to be effectively dissipated to prevent damage to the device and ensure consistent performance. This necessitates the inclusion of sophisticated thermal management solutions, such as heat sinks or advanced materials, further increasing the manufacturing expenses.

Size Constraints and Miniaturization Techniques

Miniaturizing the LiDAR system to fit within the confines of a smartphone is a significant engineering feat. Current LiDAR modules are relatively bulky compared to other smartphone components. This necessitates the development of novel micro-electromechanical systems (MEMS) and advanced packaging techniques. For instance, manufacturers are exploring the use of vertical cavity surface-emitting lasers (VCSELs) due to their smaller size and lower power consumption compared to edge-emitting lasers. Innovative approaches to integrating the optics and electronics, such as 3D stacking and wafer-level packaging, are also being explored to reduce the overall footprint of the LiDAR module. The cost implications of these advanced manufacturing processes are substantial, requiring specialized equipment and expertise. For example, the adoption of advanced packaging techniques such as System-in-Package (SiP) adds to the cost of the module, as it necessitates specialized assembly and testing processes.

Power Consumption and Thermal Management

The high power consumption of LiDAR is another significant challenge. LiDAR systems require significant energy to operate the laser, process the received signals, and manage the associated electronics. This increased power draw necessitates either larger battery capacities or more efficient power management units (PMUs), both of which contribute to increased manufacturing costs. Moreover, the heat generated by the LiDAR module during operation requires effective thermal management to prevent overheating and potential damage to the device. Sophisticated thermal management solutions, such as advanced heat sinks or thermal interface materials, need to be integrated into the design, further increasing the overall cost. Apple’s implementation of LiDAR in the iPhone, for example, demonstrates the complexity involved. While the specific details of their thermal management solution are proprietary, it’s clear that effective heat dissipation is a crucial aspect of their design, contributing to the overall manufacturing cost.

Innovative Solutions to Overcome Integration Challenges

Overcoming these integration challenges requires a multi-pronged approach involving materials science, micro-fabrication, and system design innovations. One promising area is the development of more energy-efficient LiDAR components. Research into low-power lasers, improved signal processing algorithms, and more efficient electronic circuitry is ongoing. Furthermore, advancements in packaging technologies, such as 3D integration and advanced substrate materials, are enabling the creation of smaller and more efficient LiDAR modules. The exploration of alternative LiDAR architectures, such as solid-state LiDAR, which eliminates the need for moving parts, offers the potential for significant size and power reduction. These innovative solutions, while promising, require significant research and development investments, which ultimately translate to higher initial manufacturing costs until economies of scale are achieved.

Power Consumption

LiDAR’s power demands represent a significant hurdle in its integration into smartphones. The high-speed spinning components and complex signal processing required for accurate 3D mapping consume considerable energy, directly impacting battery life, a critical factor for consumer acceptance. This section examines the energy implications of integrating LiDAR into smartphones and its influence on manufacturing costs.

Miniaturized LiDAR systems, while achieving impressive depth sensing capabilities, are still relatively power-hungry compared to other smartphone sensors. The energy consumed is a function of several factors including the laser’s power, the frequency of scanning, and the processing power needed to interpret the returned signals. Efficient power management is crucial to mitigate this impact and maintain acceptable battery life. This necessitates careful design choices and the integration of power-saving technologies, thereby affecting the overall cost of the device.

LiDAR Power Consumption and Battery Life

The power consumption of a LiDAR system in a smartphone can significantly reduce battery life, depending on the implementation and usage. For example, continuous use of LiDAR for augmented reality applications or high-resolution 3D scanning could drain the battery much faster than typical smartphone usage patterns. Manufacturers need to strike a balance between LiDAR functionality and battery life, potentially requiring larger batteries or more sophisticated power management strategies. This increased battery capacity or advanced power management circuitry directly contributes to the overall manufacturing cost. For instance, a hypothetical scenario could show a 20% increase in battery size resulting in a 5-10% increase in material costs and manufacturing complexity.

Power Management Techniques and Cost Implications

Implementing efficient power management techniques is vital to minimize the impact of LiDAR on battery life and ultimately reduce the overall cost of the device. These techniques can include: low-power modes that reduce the LiDAR’s operating frequency or resolution when not actively used; intelligent power scheduling that prioritizes other functions when LiDAR is not needed; and the use of highly efficient power amplifiers and signal processing circuits. The cost of integrating these sophisticated power management solutions needs to be weighed against the potential benefits of improved battery life and user experience. The development and integration of such systems can increase the research and development costs and manufacturing complexity, leading to a higher overall price.

Comparison with Other Power-Hungry Components

While LiDAR is a relatively power-intensive component, its energy consumption should be considered in the context of other power-hungry smartphone features. The processor, display, and cellular modem are major power consumers. LiDAR’s power draw might be comparable to or even less than some of these components depending on usage patterns and system design. A comprehensive power budget analysis is crucial to understand the trade-offs between different components and their impact on battery life. For instance, a high-refresh-rate display might consume more power than a LiDAR system operating in a low-power mode. However, the development and manufacturing cost of the high-refresh-rate display is also higher than the LiDAR system. The overall cost implication needs to be carefully assessed to optimize power consumption and maintain profitability.

Software and Algorithms

The software and algorithms necessary for processing LiDAR data in smartphones represent a significant cost factor for manufacturers. This cost encompasses not only the initial development but also ongoing maintenance, updates, and optimization for various hardware configurations and application scenarios. The complexity of these algorithms, coupled with the real-time processing requirements, necessitates substantial investment in both human expertise and computational resources.

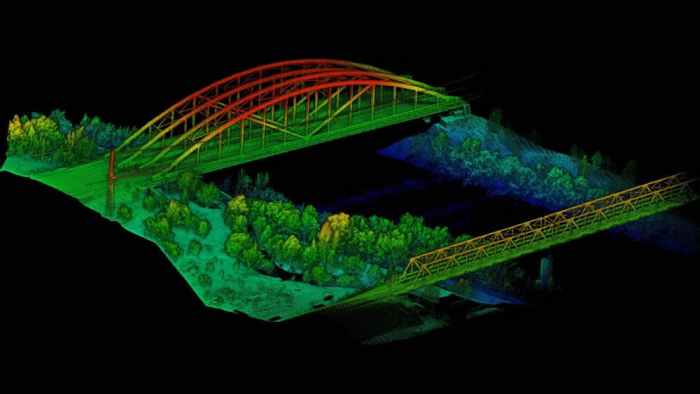

The core challenge lies in efficiently converting raw LiDAR point cloud data into meaningful representations of the environment. This involves several computationally intensive steps, including point cloud filtering, registration, segmentation, and feature extraction. These processes require sophisticated algorithms to handle noise, outliers, and varying lighting conditions, ultimately generating accurate 3D models suitable for applications like augmented reality (AR) and 3D mapping. Furthermore, these algorithms must be optimized for low-power consumption to extend smartphone battery life, adding another layer of complexity and development time.

LiDAR Data Processing Algorithm Development Costs

Developing the algorithms for LiDAR data processing in smartphones involves substantial investment in skilled engineers and researchers specializing in computer vision, signal processing, and machine learning. The cost is directly related to the complexity of the algorithms, the desired accuracy, and the time required for development and testing. For instance, a simplified algorithm might suffice for basic depth sensing, while a more sophisticated algorithm would be needed for high-resolution 3D mapping, increasing the development cost proportionally. Consider a hypothetical scenario where a team of five experienced engineers spends a year developing a sophisticated LiDAR processing algorithm. Given average salaries for such specialists, the personnel costs alone could easily reach hundreds of thousands of dollars, excluding overhead and other associated expenses.

Computational Resource Requirements and Costs

Real-time processing of LiDAR data requires significant computational power. The sheer volume of data generated by LiDAR sensors demands powerful processors and specialized hardware accelerators to perform the necessary computations within the timeframe required for a smooth user experience. This translates into increased costs for the smartphone’s system-on-a-chip (SoC), which must incorporate high-performance processing units capable of handling the computational load. For example, integrating a dedicated neural processing unit (NPU) optimized for LiDAR data processing would add to the overall SoC cost. Furthermore, the increased power consumption associated with these high-performance components could necessitate larger and more efficient batteries, further impacting the overall manufacturing cost.

Comparison with Other Smartphone Software Components

Compared to other smartphone software components, the cost of LiDAR-specific software and algorithms is relatively high. While operating systems, user interfaces, and basic applications represent significant software development efforts, the computational demands and algorithmic complexity of LiDAR processing are substantially greater. For example, the software for a camera app is comparatively simpler, focusing primarily on image processing and display, whereas LiDAR processing involves complex 3D data manipulation and scene understanding. The specialized expertise required, coupled with the need for real-time performance, positions LiDAR software as a more expensive component in the overall smartphone software stack. This cost difference reflects the increased complexity and specialized hardware requirements needed to support LiDAR functionality.

Research and Development Costs

The integration of LiDAR technology into smartphones represents a significant investment for manufacturers, demanding substantial research and development (R&D) expenditure across various stages, from initial concept to final product integration. These costs are not only substantial but also spread over a considerable timeframe, influencing the overall profitability of the smartphone model.

The R&D costs associated with miniaturizing LiDAR for smartphones are considerable, encompassing several key areas. Firstly, substantial investment is needed to develop and refine the miniaturized LiDAR sensor itself, including the design of micro-optical components, the selection of appropriate light sources and detectors, and the development of sophisticated signal processing algorithms to ensure accuracy and reliability within the confines of a smartphone. Secondly, significant resources are allocated to integrating the LiDAR sensor seamlessly with existing smartphone components and software, addressing challenges related to power consumption, thermal management, and data processing. Finally, rigorous testing and validation are required to ensure the LiDAR system’s performance meets the required standards in various environmental conditions and use cases. Estimates for the R&D investment in a single LiDAR smartphone model range from tens to hundreds of millions of dollars, depending on the sophistication of the technology and the manufacturer’s resources.

Amortization of R&D Costs

R&D costs for LiDAR technology are amortized over the projected sales volume and lifespan of a particular smartphone model. This means that the initial hefty investment is spread across the anticipated number of units sold over its market lifecycle, typically two to three years. A successful model with high sales volume will amortize the R&D cost more quickly and efficiently, resulting in a higher profit margin per unit. Conversely, a less successful model with lower sales will result in a longer amortization period and potentially lower profitability, even if the per-unit production cost is low. For instance, if a company invests $50 million in R&D for a LiDAR smartphone and sells 10 million units, the R&D cost per unit is $5. However, if only 1 million units are sold, the cost increases to $50 per unit. This significantly impacts pricing strategy and overall profitability.

Comparison with Other Smartphone Technologies

The R&D costs of LiDAR integration compare significantly with other advanced smartphone technologies. While the precise figures are often kept confidential by manufacturers, it’s generally accepted that LiDAR development is among the most expensive endeavors. Compared to developing a new camera sensor or improving processor performance, the complexity of miniaturizing and integrating a functional LiDAR system into a smartphone presents unique challenges, driving up the R&D expenditure. For example, the development of high-resolution camera systems, while demanding, involves relatively mature technologies and established supply chains. In contrast, LiDAR’s relatively nascent nature in the smartphone sector requires more extensive research and development, leading to higher upfront costs. The development of 5G modem technology, while also demanding, is likely to have a comparable R&D investment, but the economies of scale and wider industry adoption could result in a faster amortization. Ultimately, the cost-effectiveness of LiDAR in smartphones hinges on its successful adoption and the resulting sales volume.

Supply Chain and Logistics

The successful integration of LiDAR into smartphones hinges not only on technological advancements but also on the efficient management of the complex supply chain and logistics involved. The intricate network of suppliers, manufacturers, and distributors plays a crucial role in determining the final cost of the device and its time to market. Understanding the dynamics of this supply chain is vital for manufacturers aiming to bring cost-effective LiDAR-enabled smartphones to consumers.

The LiDAR supply chain for smartphones involves numerous key players, each contributing specific components or expertise. These players span the globe, from raw material suppliers to specialized component manufacturers and ultimately, the original equipment manufacturers (OEMs) assembling the final product. The complexity and geographical dispersion of this network directly impact cost and delivery timelines.

Key Players in the LiDAR Smartphone Supply Chain

The LiDAR supply chain for smartphones is multifaceted. Major players include companies specializing in MEMS (Microelectromechanical Systems) for the scanning mirrors, semiconductor manufacturers providing the necessary processing chips and sensors, companies producing the laser diodes, and the assembly houses responsible for integrating the LiDAR module into the smartphone. Furthermore, software developers play a critical role in providing the algorithms and processing capabilities needed to interpret the LiDAR data. Finally, the OEMs, such as Apple, Samsung, and Google, integrate the finished LiDAR module into their devices. Each stage of this process contributes to the overall cost. For instance, the scarcity of certain specialized components, like high-performance MEMS mirrors, can significantly drive up prices.

Impact of Supply Chain Dynamics on LiDAR Component Costs

Fluctuations in the global economy, geopolitical events, and natural disasters can all disrupt the LiDAR supply chain, leading to shortages and price increases. For example, the COVID-19 pandemic highlighted the fragility of global supply chains, causing significant delays and increased costs for many components, including those used in LiDAR systems. Similarly, trade wars or sanctions can restrict access to specific materials or manufacturing capabilities, further impacting component costs. The reliance on specific geographical regions for certain components also creates vulnerabilities. For example, a significant portion of rare earth elements crucial for laser diodes originates from a limited number of countries, making the supply susceptible to political or economic instability. These factors contribute to cost uncertainty and potential price volatility for LiDAR components.

Logistics and Transportation Costs in LiDAR Integration

The transportation of components and finished goods across international borders adds another layer of complexity and cost to LiDAR integration. Shipping costs, insurance, customs duties, and potential delays all contribute to the overall expense. The delicate nature of LiDAR components necessitates specialized packaging and handling, further increasing logistics costs. The distance between manufacturing sites and assembly plants also plays a significant role; longer distances lead to higher transportation expenses and increased lead times. For example, if key components are manufactured in Asia and the final assembly takes place in Europe or North America, the transportation costs can be substantial, directly impacting the final price of the smartphone. Efficient logistics management, including optimized routing and inventory control, is therefore crucial for minimizing these costs and ensuring timely delivery.

Consumer Perception and Pricing

The integration of LiDAR technology into smartphones presents a complex interplay between technological advancement, manufacturing costs, and consumer acceptance, ultimately shaping the pricing strategies of manufacturers. Consumer perception directly influences the price point at which a smartphone with LiDAR can be successfully marketed and sold, creating a delicate balancing act for companies. A positive perception, driven by understanding and appreciating the technology’s capabilities, can justify a higher price point, while a negative perception, potentially due to a lack of awareness or perceived unnecessary added cost, may necessitate a lower, potentially less profitable, price.

Consumer willingness to pay for LiDAR-equipped smartphones is directly correlated with their understanding of the technology’s benefits and their perceived value. The added features enabled by LiDAR, such as enhanced augmented reality experiences, improved depth sensing for photography, and advanced 3D mapping capabilities, must be effectively communicated to consumers to justify the premium price. This communication needs to translate the technological advancements into tangible benefits that resonate with the target audience, convincing them that the additional cost is worthwhile. Conversely, if consumers perceive the benefits as marginal or unnecessary, they are less likely to pay a premium, forcing manufacturers to reconsider their pricing strategy.

LiDAR Pricing Strategies Across Manufacturers

Different manufacturers have adopted varying pricing strategies for smartphones incorporating LiDAR technology. Apple, for instance, has integrated LiDAR into its higher-end iPhone models, reflecting a strategy of positioning the technology as a premium feature for its flagship devices. This approach implicitly suggests that the target consumer base for LiDAR is willing to pay a significant premium for the enhanced capabilities. In contrast, other manufacturers have chosen to integrate LiDAR into a broader range of their smartphone models, potentially targeting a wider consumer base willing to accept a smaller price increase. This approach might suggest a focus on broader market penetration rather than maximizing profit margins per unit. The specific pricing strategies adopted by each manufacturer reflect their assessment of consumer perception and willingness to pay within their respective target markets. The success of these different strategies ultimately depends on the accuracy of these assessments and the effectiveness of their marketing efforts.

Future Cost Projections

Predicting the future cost of LiDAR in smartphones requires considering several dynamic factors. While current costs are relatively high, significant cost reductions are anticipated over the next five years, driven primarily by technological advancements and economies of scale. This section will explore projected cost reductions and their impact on market adoption.

LiDAR Cost Projections in Smartphones, LiDAR technology in smartphones: cost implications for manufacturers.

The following table provides estimated cost projections for LiDAR integration into smartphones over the next five years. These projections are based on current trends in miniaturization, manufacturing process improvements, and increasing market demand. It is important to note that these are estimates and actual costs may vary depending on unforeseen technological breakthroughs and market conditions. Comparable cost reductions were observed with other previously expensive smartphone technologies like high-resolution cameras and advanced processors.

| Year | Estimated Cost per Unit (USD) | Projected Market Share (%) | Impact on Smartphone Price (USD) |

|---|---|---|---|

| 2024 | $50 – $75 | 5% | $30 – $50 |

| 2025 | $30 – $50 | 15% | $15 – $30 |

| 2026 | $15 – $30 | 30% | $5 – $15 |

| 2027 | $10 – $20 | 50% | $2 – $10 |

| 2028 | $5 – $10 | 75% | Minimal to Negligible |

Factors Driving Down LiDAR Costs

Several key factors will contribute to the significant decrease in LiDAR costs. Firstly, ongoing research and development in solid-state LiDAR technology promises smaller, more efficient, and less expensive components compared to mechanical LiDAR systems. Secondly, increased production volumes will lead to economies of scale, significantly reducing manufacturing costs per unit. Thirdly, advancements in manufacturing processes, such as advanced packaging techniques and the use of silicon photonics, will further streamline production and reduce costs. Finally, increased competition among LiDAR manufacturers will drive down prices as companies strive for market share.

Scenario: LiDAR as a Standard Smartphone Feature

A plausible scenario envisions LiDAR becoming a standard feature in mid-range and flagship smartphones by 2027 or 2028. As the cost per unit falls below $10, the incremental cost to the manufacturer becomes negligible, allowing for its inclusion without significantly impacting the overall device price. This will be further facilitated by the increasing demand for advanced 3D sensing capabilities, making LiDAR a desirable feature for consumers. This scenario parallels the adoption of other technologies, such as fingerprint sensors and high-resolution cameras, which initially commanded premium prices but eventually became standard features across various price points. The widespread availability of affordable LiDAR would unlock new applications and features in augmented reality, improved photography, and advanced depth sensing, creating a positive feedback loop driving further cost reductions and adoption.

In conclusion, while the integration of LiDAR technology into smartphones presents significant challenges and considerable upfront costs for manufacturers, the potential for market disruption and enhanced user experiences is undeniable. The future of LiDAR in smartphones hinges on overcoming current manufacturing hurdles, achieving economies of scale, and managing consumer expectations regarding pricing. As technology matures and production volumes increase, the cost of LiDAR is projected to decrease, potentially paving the way for its widespread adoption as a standard feature in future mobile devices. This will require strategic investments in research and development, efficient manufacturing processes, and a keen understanding of market demand and consumer pricing sensitivity.

FAQ Compilation: LiDAR Technology In Smartphones: Cost Implications For Manufacturers.

What are the main types of LiDAR used in smartphones?

The primary types are flash LiDAR and time-of-flight (ToF) LiDAR. Flash LiDAR uses a short pulse of light, while ToF LiDAR measures the time it takes for light to return.

How does LiDAR impact smartphone battery life?

LiDAR sensors can be relatively power-hungry, potentially reducing battery life. Power management techniques are crucial to mitigate this.

What are the ethical concerns surrounding LiDAR in smartphones?

Concerns exist regarding data privacy and potential misuse of depth-sensing capabilities. Careful consideration of data security is paramount.

Will LiDAR become a standard feature in all smartphones?

It’s uncertain. Cost and consumer demand will be determining factors. It’s more likely to initially be a premium feature.