Filament: The Versatile Material Revolutionizing Manufacturing

Filament, in its most basic form, is a long, thin strand of material used in 3D printing and other manufacturing processes. While the concept might seem simple, the reality is far more complex. Filament encompasses a vast range of materials, each with unique properties and applications, making it a cornerstone of modern manufacturing, rapid prototyping, and even artistic expression. This article delves into the world of filament, exploring its different types, properties, applications, and the factors that influence its performance.

A World of Materials: Exploring the Diverse Landscape of Filaments

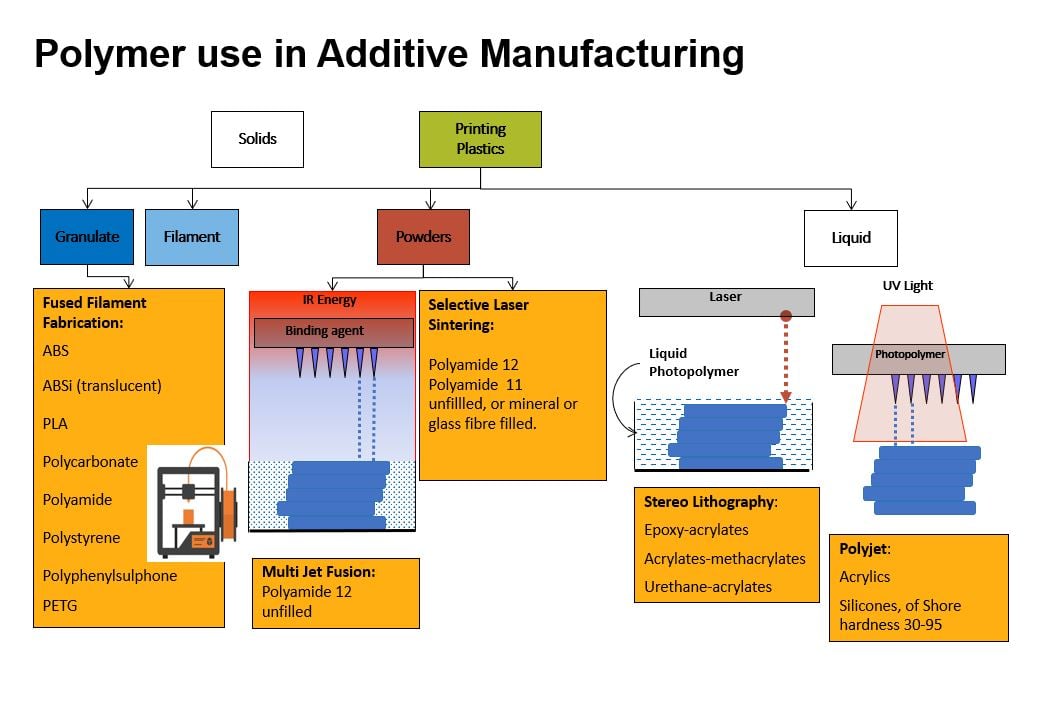

The defining characteristic of filament lies in its material composition. This single factor dictates its strength, flexibility, temperature resistance, and suitability for various applications. Here’s a look at some of the most popular filament types:

-

PLA (Polylactic Acid): The workhorse of 3D printing, PLA is a biodegradable thermoplastic derived from renewable resources like cornstarch or sugarcane. It’s known for its ease of use, low printing temperature, and minimal warping. PLA is ideal for beginners and projects that don’t require high strength or heat resistance, such as prototypes, decorative items, and educational models.

-

ABS (Acrylonitrile Butadiene Styrene): A more robust and durable option compared to PLA, ABS is a petroleum-based thermoplastic known for its higher impact resistance and temperature tolerance. It’s commonly used in automotive parts, electronic enclosures, and toys. However, ABS requires higher printing temperatures and is more prone to warping, demanding a heated bed and potentially an enclosed printer.

-

PETG (Polyethylene Terephthalate Glycol-modified): Bridging the gap between PLA and ABS, PETG offers a good balance of strength, flexibility, and ease of printing. It’s also food-safe, making it suitable for containers and kitchenware. PETG is known for its good layer adhesion and resistance to chemicals, making it a versatile choice for a wide range of applications.

-

Nylon: Renowned for its exceptional strength, flexibility, and abrasion resistance, nylon is a polyamide thermoplastic used in demanding applications like gears, bearings, and functional prototypes. It’s also hygroscopic, meaning it absorbs moisture from the air, which can affect print quality. Therefore, nylon filament needs to be stored in a dry environment and often requires a specialized drying process before printing.

-

TPU (Thermoplastic Polyurethane): This flexible filament allows for the creation of rubber-like parts with varying degrees of hardness. TPU is used in applications requiring shock absorption, vibration damping, and flexibility, such as phone cases, gaskets, and wearable devices. Printing with TPU can be challenging due to its flexibility, requiring careful calibration of printer settings.

Polycarbonate (PC): Offering exceptional strength, heat resistance, and impact resistance, polycarbonate is a high-performance thermoplastic used in demanding applications like automotive parts, safety glasses, and electronic components. It requires very high printing temperatures and a heated bed, making it more challenging to print than other filaments.

-

Specialty Filaments: Beyond the common types, a wide array of specialty filaments cater to niche applications. These include:

- Carbon Fiber Filled Filaments: Offer increased strength and stiffness.

- Wood Filled Filaments: Impart a wood-like appearance and texture.

- Metal Filled Filaments: Contain metal particles for a metallic finish and increased density.

- Glow-in-the-Dark Filaments: Emit light in the dark after being exposed to light.

- Conductive Filaments: Allow for the creation of electronic circuits and sensors.

Properties and Performance: Understanding Filament Characteristics

The performance of a filament depends on its inherent properties, which are influenced by its material composition and manufacturing process. Key properties to consider include:

- Tensile Strength: The amount of stress a filament can withstand before breaking.

- Flexural Strength: The amount of stress a filament can withstand before bending or breaking.

- Impact Strength: The ability of a filament to resist sudden impacts without fracturing.

- Heat Resistance: The temperature at which a filament begins to soften or deform.

- Elongation at Break: The amount a filament can stretch before breaking.

- Glass Transition Temperature (Tg): The temperature at which a material transitions from a rigid, glassy state to a more flexible, rubbery state.

- Melt Flow Index (MFI): A measure of the ease with which a thermoplastic material flows under a specific temperature and pressure.

- Diameter Tolerance: The consistency of the filament’s diameter, which is crucial for consistent extrusion.

- Moisture Absorption: The tendency of a filament to absorb moisture from the air, which can affect print quality.

Understanding these properties is crucial for selecting the right filament for a specific application and optimizing print settings for optimal performance.

Applications Across Industries: The Versatility of Filament

Filament’s versatility has made it an indispensable material in a wide range of industries, including:

- Manufacturing: Rapid prototyping, tooling, jigs and fixtures, custom parts, and low-volume production.

- Aerospace: Lightweight components, custom tooling, and prototyping.

- Automotive: Prototyping, custom parts, and tooling.

- Medical: Surgical guides, prosthetics, and custom implants.

- Education: Teaching aid, model making, and student projects.

- Architecture: Architectural models and prototypes.

- Consumer Products: Toys, decorative items, and functional prototypes.

- Art and Design: Sculptures, jewelry, and custom artwork.

The ability to quickly and affordably create custom parts and prototypes has revolutionized product development cycles and enabled innovation across various industries.

Factors Influencing Filament Performance: Optimizing Print Quality

Achieving optimal print quality with filament requires careful consideration of various factors, including:

- Printer Settings: Printing temperature, print speed, layer height, infill density, and support structures all play a crucial role in the final outcome.

- Bed Adhesion: Ensuring that the first layer of the print adheres properly to the build plate is essential for preventing warping and ensuring successful prints.

- Filament Storage: Storing filament in a dry environment is crucial for preventing moisture absorption, which can lead to printing defects.

- Filament Diameter: Consistent filament diameter is essential for consistent extrusion and print quality.

- Printer Calibration: Regularly calibrating the printer ensures accurate movement and proper extrusion.

- Nozzle Size: The size of the nozzle affects the resolution and speed of the print.

By carefully controlling these factors, users can optimize print quality and achieve the desired results.

The Future of Filament: Innovation and Sustainability

The field of filament technology is constantly evolving, with ongoing research and development focused on:

- New Materials: Exploring new polymers and composite materials to create filaments with enhanced properties and functionalities.

- Sustainable Materials: Developing biodegradable and bio-based filaments to reduce the environmental impact of 3D printing.

- Improved Printing Processes: Optimizing printing parameters and developing new printing techniques to improve print quality and efficiency.

- Smart Filaments: Incorporating sensors and actuators into filaments to create smart objects and devices.

As technology advances, filament will continue to play a vital role in shaping the future of manufacturing, design, and innovation.

FAQ: Common Questions About Filament

- What is the best filament for beginners? PLA is generally considered the best filament for beginners due to its ease of use, low printing temperature, and minimal warping.

- How do I store filament properly? Filament should be stored in a dry, airtight container with desiccant to prevent moisture absorption.

- What is the difference between PLA and ABS? PLA is a biodegradable thermoplastic derived from renewable resources, while ABS is a petroleum-based thermoplastic known for its higher strength and heat resistance.

- What is warping and how can I prevent it? Warping is the tendency of a print to lift off the build plate during printing. It can be prevented by using a heated bed, applying an adhesive to the build plate, and adjusting printer settings.

- What is the best way to troubleshoot printing problems? Start by checking the filament diameter, printing temperature, bed adhesion, and printer calibration. Consult online resources and forums for specific troubleshooting tips.

- Can I recycle 3D printing filament? Some types of filament, such as PLA, can be recycled, but recycling options may vary depending on your location.

- What does food-safe filament mean? Food-safe filament means that the material is approved for contact with food. PETG is a common example. However, the printing process itself can introduce bacteria, so thorough cleaning is essential.

Conclusion: Filament – A Transformative Material

Filament is more than just a spool of plastic; it’s a transformative material that is revolutionizing manufacturing, design, and innovation. Its versatility, affordability, and ease of use have made it an indispensable tool for engineers, designers, artists, and hobbyists alike. As technology continues to advance, filament will undoubtedly play an even greater role in shaping the future of our world. From creating custom prosthetics to building intricate architectural models, the possibilities are endless. By understanding the properties, applications, and factors influencing filament performance, we can unlock its full potential and harness its power to create a better future. Its continued development, especially in sustainable materials, promises an even brighter future for this versatile material.